MEIDEN Group

“Meidensha will continue taking on the challenges of creating new technologies and generating new value to help create a world of greater abundance and comfort in future.”

(Akio Inoue, President Meidensha Corporation)

For more than 60 years, we have been producing top-quality surge arresters at our Hermsdorf site in the green heart of Germany. The company can look back on a history of more than 100 years.

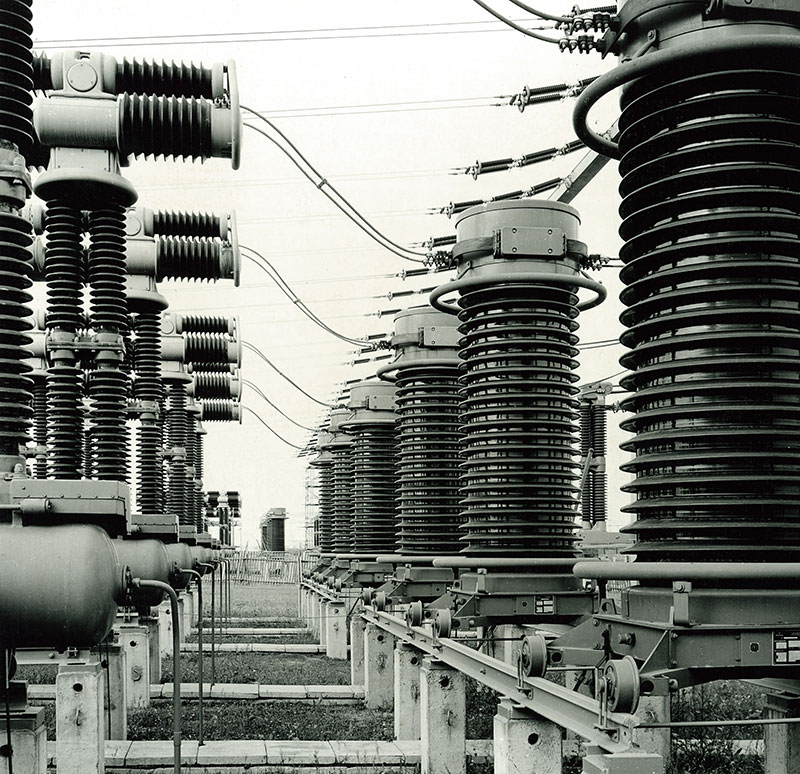

Today, Tridelta surge arresters stand for best quality, high reliability and freedom from maintenance over the entire service life worldwide.

Our portfolio of metal oxide arresters for system voltages from 1 kV to 800 kV is supplemented by arresters for customer-specific special applications.

Our arresters are successfully in use in over 120 countries around the world and have proven themselves even under extreme climatic conditions. In addition to the use of first-class components, we see the readiness for action and the high reliability of our team as a guarantee for success.

In order to be prepared for future market requirements, we are always looking for committed colleagues who would like to become part of our success story.

You can find more information on our career page.

What sets us apart is not just our first-class products. There is more to learn.

“Meidensha will continue taking on the challenges of creating new technologies and generating new value to help create a world of greater abundance and comfort in future.”

(Akio Inoue, President Meidensha Corporation)

inoye-scaled (2)

Meidensha Surge arresters

Meidensha has pioneered many new technologies, including the development of the world’s first metal oxide surge arrestor (MOSA) for electrical systems in 1975, which set new industrial standards for power system protection and was awarded an IEEE Milestone in 2014.

R&D Center for Metal Oxide Blocks

Metal oxide blocks are at the heart of surge arrester technology. Meidensha pioneered the development of metal oxide blocks for surge arresters in 1972. Drawing on this experience, Meidensha manufactures high quality, high performance blocks in various sizes for AC and DC applications and different installation environments.

T&D Business

Meidensha also manufactures T&D equipment such as transformers, vacuum circuit breakers, vacuum interrupters, high-voltage switchgear, mobile substations, etc., including the use of energy management systems (EMS).

For more interesting information about our parent company and historical background, please visit www.meidensha.com.

For first-class products, you need clearly defined processes. We constantly review these processes and improve them where necessary. All important information is summarized in our management manual.

Prozesslandschaft

For the health of our employees, we always attach great importance to a safe working environment. We therefore provide our employees with personal protective equipment, constantly train first aiders and rehearse what to do in various situations in the event of an emergency.

We only have our earth once. That’s why we at Tridelta Meidensha are committed to our environment through various projects. For example, we supported a local beekeeper in 2021, instruct colleagues in water and energy-saving measures, and try to create more awareness of environmental issues among our employees.

The UN has defined 17 goals to promote sustainable peace and prosperity by 2030. We, too, would like to contribute to the implementation of this global plan by 2030. You can also find more information for your own commitment here: https://unric.org/de/17ziele/

We tackle it

You too can join in and learn more at 17Goals.com.

We have focused on these six goals because we have already introduced the first measures here.

Tridelta Meidensha has a modern and efficient high voltage laboratory where type tests according to IEC 60099-4 can be performed. The following test equipment is available for this purpose:

-impulse generator up to 1.2 MV

-AC transformer 600 kV

-Varistor test equipment IP 225/100

-high current surge generator 100 kA

-long wave generator for line discharge class 1 to 5

-test facility 5000 h weather aging test

-climate chamber -40°C to +100°C

-Mechanical bending and tensile test equipment 30,000 N

Test lab

Values_Graphics

Employees

Our employees are one of the pillars of our success. For this reason, we want to create a pleasant working environment for them in which they can work safely and effectively. Daily improvements within the framework of LEAN management are also an opportunity to actively help shape the company.

Customers

Our customers value the highest quality and best service. We work every day to meet this requirement. Our figures tell us that we have managed this well in the past and we look to our entrepreneurial future with hope.

Stakeholders

As part of the MEIDEN Group based in Japan, we are accountable to our parent company. By involving colleagues from Japan in our production facility in Hermsdorf, we create the opportunity to let our parent company participate in our processes up close.

This well-known saying has long since lost its validity for us. We optimize our processes every day to become faster, more efficient and better for you.

On our LinkedIn page, we will periodically update you on our LEAN culture, LEAN terminology, and impressive people with high impact on LEAN management. Follow us for more on Tridelta Meidensha on LinkedIn

Cleanliness

We leave every place better than we found it. This also applies to cleanliness. We want you and us to feel comfortable in our building.

Standardization

We want to set standards. In the long term, these should mean that our work can be done more easily and quickly and that almost every colleague can work at every workstation.

Communication

We attach great importance to open communication. For this reason, we hold a daily round of talks in which important topics are addressed on a daily basis in order to find solutions immediately. Furthermore, important dates and improvements are discussed in this round.

Where we come from, we know. Where we are going, we will find out.

As a traditional company from the green heart of Germany, we can look back on a long history.

Foundation

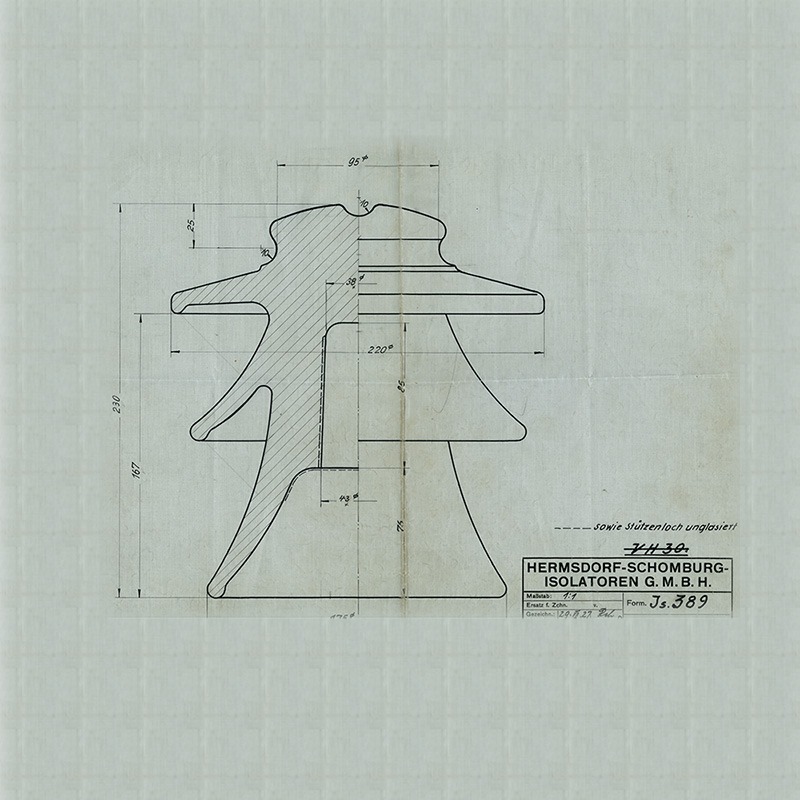

High voltage insulator “DELTA bell”

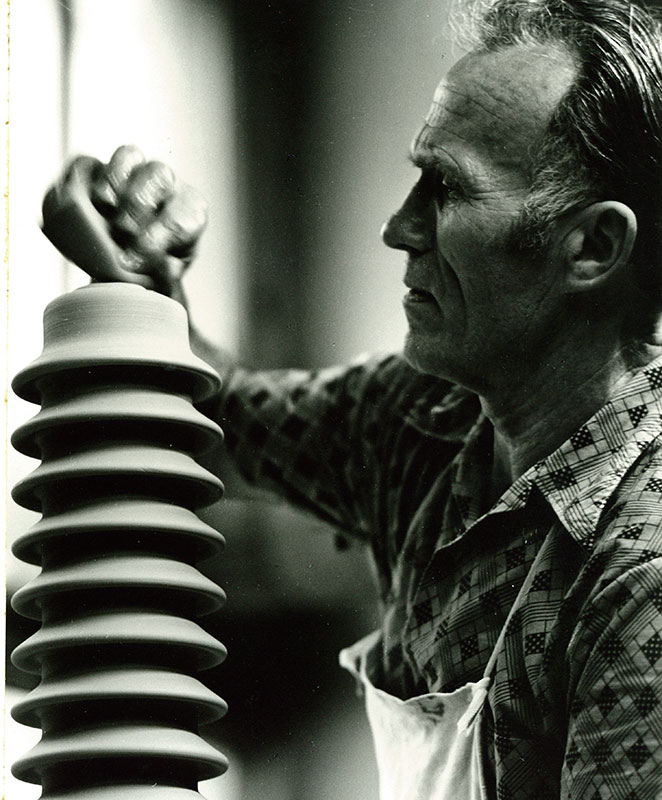

Start of insulators manufacturing

Start of 110kV insulators production

Start of arrester production

Development of the first 400kV arrester

Metal Oxide Arrester Manufacturing

Introduction of arresters in plastic housings

Development of the 800 kV arrester

Market introduction cage arrester

Tridelta becomes part of the international Meiden Group and henceforth trades as Tridelta Meidensha GmbH

Introduction smartCOUNT

Introduction of new medium voltage arresters

For our continuous growth we are always looking for motivated colleagues whether in the field of production or as a specialist. Apply now.

You are currently viewing a placeholder content from Google Maps. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information